Getting started with automated peptide synthesis: A practical guide

Peptide therapeutics are a growing area, evolving from niche research tools into established therapeutic modalities. As biotech and pharma companies invest in this expansion in peptides, the choice of synthesis technology becomes critical for success. Automated peptide synthesis offers the precision, scalability, and reliability that peptide labs require to maintain a competitive edge.

Whether you are developing peptide drug candidates, scaling up for clinical trials, or evaluating the transition from outsourcing to in-house synthesis, understanding how to implement automation effectively can determine project success and timelines.

This blog gives you a high-level overview of what you should know when getting started with automated peptide synthesis.

Introduction: The evolution of automated peptide synthesis

Automated peptide synthesis has advanced significantly since Bruce Merrifield's breakthrough in solid-phase peptide synthesis (SPPS) in 1963. What began as a manual, time-intensive process has evolved into automated systems that can synthesize multiple peptides simultaneously with high precision.

Modern automated synthesizers build on Merrifield's foundational chemistry while incorporating critical innovations like precise fluid handling, real-time monitoring, and advanced heating technologies. These systems transform complex chemistry into controlled, repeatable steps: deprotection, coupling, and washing—each precisely monitored and executed.

Key advantages of automation

Reliability

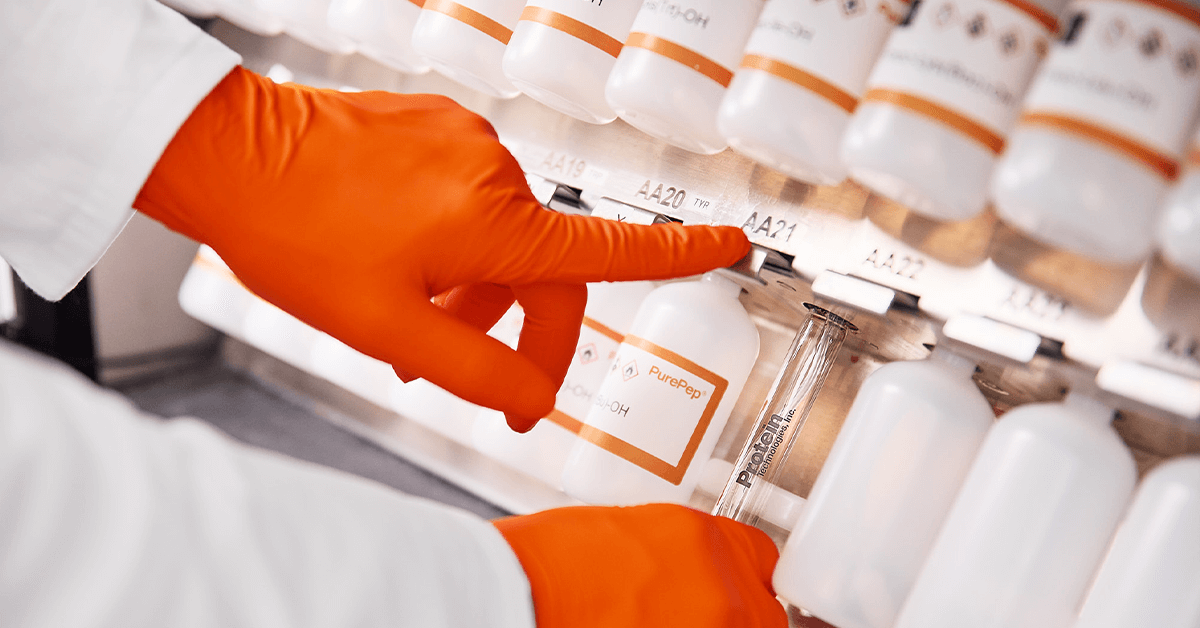

Efficient peptide synthesis relies on continuous, disruption-free workflows to maintain operational consistency in laboratories. Automation is key to achieving this consistency by minimizing human errors and delivering reproducible results across multiple syntheses. Our proprietary PurePep® Pathway technology utilizes a microfluidic design that ensures zero dead volume and reduces the risk of cross-contamination.

Flexibility

Automated systems streamline synthesis processes, significantly reducing the time required compared to manual methods or outsourced solutions. For instance, advanced platforms, such as Gyros Protein Technologies PurePep® Chorus, can complete synthesis cycles in just minutes using induction-heating technology. This capability leads to faster project turnaround, lower labor costs, and enhanced control over development timelines.

Two pillars for peptide synthesis success

Advanced synthesizer technology combining reliable fluid handling capabilities with flexible software control to automate synthesis processes. Reproducible, scalable protocols reduce human error and increase consistency.

Comprehensive service ensures success from first synthesis through long-term maintenance and implementation of advanced applications. This ongoing support encompasses expert training, rapid troubleshooting, method development, and continuous optimization guidance.

Designing a synthesis

Advanced peptide synthesis requires precise input variables to ensure high-quality results. Developing a synthesis design involves detailed consideration of materials, process optimization, and systematic troubleshooting.

Key Steps in Designing a Synthesis

Successful peptide synthesis begins with choosing appropriate reagents and optimizing reaction conditions. The following components are foundational:

1. Starting materials

- Select the appropriate resin based on sequence complexity and production scale.

- Choose a linker that suits your desired peptide’s functional group and cleavage process.

- Evaluate resin swelling behavior to determine solvent requirements and reaction volume.

- Use the UV monitoring system to verify reaction completion in real-time.

- Maintain appropriate reaction temperatures to prevent side reactions such as aspartimide formation—known to reduce crude purity.

- Adjust reagent stoichiometry and excess to drive coupling efficiency based on peptide length and difficulty.

- Implement heating solutions to accelerate coupling while preserving crude purity.

Are you ready for a hands-on session? View our on-demand webinar by Chloe Mitchell and Luisa Aguiar about Getting Started with Automated Peptide Synthesis.

PurePep Chorus: This system offers modularity for research. It can expand from 2 to 6 reaction vessels to meet changing needs. Features include induction heating and real-time UV monitoring to optimize method development and manage difficult sequences.

PurePep Chorus: This system offers modularity for research. It can expand from 2 to 6 reaction vessels to meet changing needs. Features include induction heating and real-time UV monitoring to optimize method development and manage difficult sequences.

Symphony X: A 24-channel synthesizer for high-throughput parallel synthesis. Each channel functions independently, allowing simultaneous use of different protocols, scales, and sequences. This is ideal for peptide library production and screening campaigns.

Symphony X: A 24-channel synthesizer for high-throughput parallel synthesis. Each channel functions independently, allowing simultaneous use of different protocols, scales, and sequences. This is ideal for peptide library production and screening campaigns.

PurePep Sonata+: A pilot-scale synthesizer for clinical production. It offers a 10–200 mmol synthesis scale and GMP-compliant software, bridging the gap between research and manufacturing.

PurePep Sonata+: A pilot-scale synthesizer for clinical production. It offers a 10–200 mmol synthesis scale and GMP-compliant software, bridging the gap between research and manufacturing.

Summary: Implementing automation to accelerate innovation

Automated peptide synthesis represents a technological advancement. By eliminating the manual aspects of synthesis, automation enables scientists to focus on discovering and developing peptide therapeutics.

Success depends on selecting the appropriate synthesizer and support service partner for your specific requirements. Whether you require the research flexibility of the PurePep Chorus, the high-throughput capability of Symphony X, or the large-scale production of PurePep Sonata+, proper support and services can transform your peptide development timeline, success rate, and workflow efficiency.

Curious to learn more about peptide therapeutics and automated peptide synthesis?

Please don't hesitate to contact our team to schedule a consultation.