Three bottlenecks slowing down your peptide purification workflow

Peptide purification workflows constantly face challenges that can delay timelines and compromise research outcomes. Despite advances in synthesis technology, three critical bottlenecks continue to frustrate researchers and limit laboratory productivity.

Understanding these obstacles—and their solutions—can transform your approach to peptide purification, particularly when working with challenging peptide sequences and in high-throughput settings.

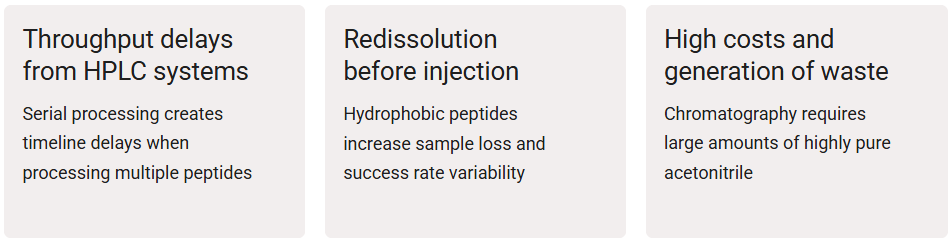

The three major workflow bottlenecks

Throughput delays from HPLC systems

⌛HPLC systems create significant timeline delays, especially when processing multiple peptides or working with hydrophobic sequences that resist standard purification methods. The serial processing means that purifying 8 or more peptides can extend timelines by days, creating bottlenecks that slow down drug discovery cycles.

The challenge becomes more pronounced with difficult peptides. Hydrophilic sequences may flush through columns without adequate retention, while hydrophobic peptides aggregate or fail to elute cleanly. Method development for each sequence adds another layer of complexity and time.

🧪Precipitation and redissolution challenges

Traditional workflows require the precipitation of peptides in ether and their subsequent redissolution before HPLC injection. This tedious, multi-step process increases sample loss and introduces variability in yield. A significant amount of manual work is required for every purification cycle.

Hydrophobic peptides present particular challenges during redissolution. Some sequences may not dissolve after precipitation, resulting in complete workflow failures. Even when dissolution is successful, the process introduces uncertainty, and manual handling steps increase the risk of errors.

💵High costs and the generation of waste

Increased success rates lead to significant cost savings as failed purifications waste time and materials. When hydrophobic peptides fail to redissolve or chromatography fails to achieve the target purity, the entire synthesis effort may be lost.

Time-intensive workflows consume large solvent volumes, typically around 600 mL per HPLC run. This consumption pattern increases operational costs while generating substantial waste that impacts your laboratory's environmental footprint.

PEC 2.0: Addressing all three bottlenecks

PurePep EasyClean (PEC™) 2.0 introduces a redissolution-free workflow from synthesis to purification that directly addresses these challenges through TFA-stable beads, enabling direct immobilization from the TFA cleavage cocktail.

This approach eliminates the precipitation and redissolution steps after synthesis, enabling the parallel processing of up to 8 peptides per batch in a seamless protocol within a single day using the PurePep EasyClean Starter Kit.

Would you like to dive deeper into the details, including the scientific background and video material? Visit our dedicated PEC 2.0 Resource Hub.

Key benefits of the PEC 2.0 approach

🚀Speed and reliability combined

The redissolution-free workflow increases your success rate, especially with challenging peptides that fail to redissolve after precipitation. Moreover, the chemo-selective isolation mechanism can isolate even the smallest peptide content from your crude mixture.

♻️Environmental efficiency

The streamlined workflow reduces solvent consumption to approximately 50 mL per run—a 12x reduction compared to conventional HPLC workflows. This efficiency supports laboratory sustainability goals while reducing operational costs.

Technology comparison PEC 2.0 with Starter Kits vs. chromatography for the purification of 16 peptides.

|

PEC 2.0 |

Chromatography |

|

| Format | Ready-to-use kits | HPLC |

| Workflow | Redissolution-free | Redissolution before injection |

| Method development | Universal protocol | Sequence specific |

| Batch size | Parallel (up to 16) | Serial (one at a time) |

| Time | 1-day | 4-days |

| Success rate* | 99% (in a representative study) | 82% (in a representative study) |

| Solvent per run | ~50 mL | ~600 mL |

*defined as the percentage of assay-ready peptides obtained from the total batch of 384 peptides with PEC-grade quality

Moving beyond traditional purification bottlenecks

PEC 2.0 provides a complementary approach to HPLC, addressing specific workflow failures while maintaining the quality standards required for functional assays. The redissolution-free workflow eliminates the most problematic steps in traditional purification while supporting parallel processing needs.

For laboratories facing HPLC bottlenecks or struggling with challenging peptide sequences, PEC 2.0 offers a validated solution that delivers PEC-grade quality peptides, ready for functional assays. The approach is particularly beneficial for hydrophobic peptides that resist conventional purification methods and research programs requiring higher throughput.

Ready to eliminate these bottlenecks from your workflow? Explore PEC 2.0 and experience the difference that redissolution-free purification can make for your peptide discovery programs.